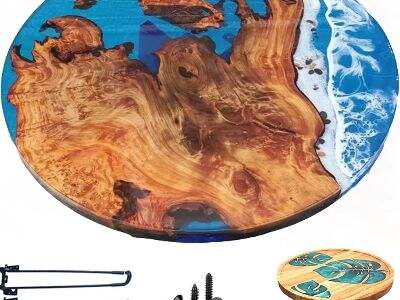

Epoxy-kunst med bølgeeffekt er en fantastisk måte å ta med sjøens utseende og følelse inn i ditt hjem. Denne teknikken baserer seg på bruk av farget epoxyharpu, som sterkt minner om havvann, bølger og skum. Andre design er flate og glatte, mens noen inkluderer en 3D-effekt som gir en illusjon av bølger som ser ut til å bevege seg. Hos GOERNER lager vi vår epoxy med bølgeeffekt etter høye standarder, slik at du får best mulige resultater hver gang. Uansett om du velger et flatt design eller noe mer detaljert med 3D-effekt, vil mestring av grunnleggende teknikker tillate deg å lage imponerende bølgekunst som tiltrekker seg oppmerksomhet

Hvorfor teknikker for epoxy med bølgeeffekt er ideelle for grossistkunder

Andre grossistkunder ønsker produkter som er enkle å selge og har bred appell. Bølgeeffekt epoxi kunst er egnet i denne forstand, ettersom det er noe mange beundrer med havet og ønsker å ta en del av med seg hjem til husene og kontorene sine. Hos GOERNER produserer vi produkter du kan stole på, slik at grossister vet at de hele tiden får produkt av samme høye kvalitet. De flate designene er enkle og raske å lage, noe som gjør dem egnet for store ordre. Samtidig skaper 3D-effekter variasjon og tiltrekker kunder som ønsker noe mer spesielt. Denne kombinasjonen av valg har bidratt til at havbølge-epoxy har blitt ett av bestsellerproduktene for gavebutikker, kunstbutikker og interiørforretninger. I tillegg er epoxy ekstremt holdbart og lett å rengjøre, noe som alltid er et pluss i kundenes øyne. Når grossister kjøper GOERNERs havbølge-epoxyprodukter i større partier, får de produkter som sparer tid og minimerer søppel. Et annet aspekt er at GOERNER leverer materialer som passer godt til ulike verktøy og teknikker, slik at kjøpere kan eksperimentere og finne den ultimate stilen for sine kunder. Denne tilpasningsdyktigheten øker salgsmulighetene og fremmer gjentakende salg. Og selvfølgelig er havbølge-epoxykunst en trendfaktor som aldri går ut på dato, fordi alle liker naturlige design. Grossister som velger GOERNER-produkter får muligheten til å delta i denne stadig mer attraktive markedsplassen med trygghet

Hvordan lage en fantastisk 3D-effekt med Ocean Wave-epoxy

Å lage 3D-effekter med epoxy-effekt i havbølgeoptikk kan være litt vanskelig i begynnelsen, men sluttresultatet er svært tilfredsstillende. Hovedtrikset ligger i å lag på lag og gradvis tilføre ulike farger og strukturer. I våre design hos GOERNER anbefaler vi et klart underlag for å gi designet dybde. Deretter bruker du hvitt eller lys blått for å lage skum eller bølger øverst. Du kan legge på tykkere epoxylag for å skape bølgene, slik at de ser ekte ut og har høyde. Noen kunstnere liker å bruke verktøy – varmluftpistoler, pensler og lignende – for å forme epoxymassen mens den fremdeles er formbar. Dette hjelper til med å flytte harpiksen og lage bølgemønstre. Bland gjerne litt glitterspy eller sand i massen for økt realisme. Det er likevel lurt å gå sakte fram, fordi epoxymassen må herdes mellom hver påføring. Å redusere tiden kan føre til bobler eller uregelmessigheter. Hvis du foretrekker et flatt design, bland alle fargene sammen og hell forsiktig slik at det ikke dannes lag. Men 3D-effekter gir mer liv og får motivet til å virke som om det kommer ut fra veggen eller bordplaten. (Epoxy-sett fra GOERNER følger med tydelige instruksjoner og høykvalitetsharpiks.) Vi anbefaler også at du tar på seg vernehansker og arbeider i et rent område, slik at ingen støvpartikler eller smuss kommer ned i epoxymassen. Ved å eksperimentere med utstøping og øve deg underveis, blir det lettere! 3D epoxymaling med havbølgeeffekt Hvis det gjøres riktig, ser en 3D epoxyhavbølge ut som ekte bølger som er fanget i tid, og bringer med seg en følelse av ro, av den typen bare havet kan gi, inn i hvert rom

Hvordan Ocean Wave-epoxy fungerer gjør produkter bedre og mer vakre

Hvis du liker Ocean Wave-epoxykunst så mye som vi, så vil du virkelig ønske å se nærmere på disse spesielle teknikkene som lar deg lage design som minner om bølger i vann. Ved å bruke epoxy, en type klar, glinsende lim, kan kunstnere få havbølgene til å virke virkelige og spennende. Hos GOERNER bruker vi disse metodene til å forbedre utseendet på produkter ved å gi dem dypde og glans. Avhengig av hvordan epoxyen helles og formas, kan bølgene også virke som om de svinger, akkurat som i det virkelige havet. Dette gjør ikke bare produktet mer visuelt interessant, men det føles også glatt og sterkt å røre ved

Aeromarines metoder for Ocean Wave-epoxy forbedrer kvaliteten ved å legge på et hardt skall: Du arbeider med epoxy. Det beskytter mot krasj, vann og smuss. Slik varer produktet lenger og beholder sin skjønnhet over tid.” For eksempel, et hvilket som helst bord eller ditt kunstverk med oceanbølge epoxi vil ikke lett skades når du bruker det hver dag. Epoxybølgene reflekterer også lys på interessante måter. Dette skaper glanspunkter og skygger som gir designet et tredimensjonalt, eller 3D, utseende! Når folk ser disse bølgene, får de følelsen av at de nesten kan rekke ut og røre ved vannet. Denne visuelle effekten er så sterk fordi den holder mennesker nær naturen og vekker en følelse av ro og avslapning

Det er denne tanken om kunst og beskyttelse som har gjort goerner sine epoxyprodukter med oceanbølger så etterspurte. Farger blandes nøye, og bølgene formes med spesielle verktøy før epoxyen herder. Dette omhyggelige arbeidet gjør hvert produkt unikt og spektakulært. Med alt dette sørger GOERNER for at hvert stykke ser ut som et lite stykke hav, levende og vakkert. Derfor er teknikker med oceanbølge-epoxy ikke bare noe som ser bra ut, de gjør gjenstander sterke og mer unike

Typiske problemer ved påføring av oceanbølge-epoxy og hvordan man retter dem opp

Det er flere problemer som kan oppstå hvis du ikke er oppmerksom når du bruker teknikker med havbølge-epoksy. Hos GOERNER PATENTKNOPL BADEN har vi lært å omgå disse problemene, slik at hvert produkt ikke bare ser bra ut, men også varer lenge. Et av de typiske problemene her er bobler i epoksien. Disse boblene kan gi overflaten et ru eller skyet utseende, ikke glatt og klart som ønsket. Bobler dannes når luft blir fanget i prosessen med å blande eller helde epoksien. For å forhindre bobler, er det veldig viktig hvordan du blander epoksien – bland den sakte og målrettet. Du kan også fjerne bobler på overflaten av produktet ved hjelp av en varmepistol eller liten brenner etter utstøping, før epoksien herder

Et annet problem kan være bølger som ikke er jevne, eller farger som ikke blandes godt. Hvis du heller for raskt, kan fargene blande seg så mye at de blir grumsete eller at designet ser flatt ut. Omvendt kan fargene bli for lite spredt og bølgene se stive ut hvis epoksy helles for sakte. Her hos GOERNER heller våre kunstnere epoksy i lag og bruker verktøy som pensler eller til og med kvister for å forsiktig forme bølgene. Dette hjelper til med å styre produktet og gjøre det mer naturlig. Jeg ventet hele tiden litt mellom hvert lag slik at det kunne tørke før neste ble lagt til, noe som bidrar til å skape klare og tydelige bølger

Det kan også oppstå problemer med temperatur og luftfuktighet. Hvis det er for kaldt eller fuktig, kan epoksyen feile tørking eller føles seigtaktige. GOERNER arbeider alltid i et sterilisert, temperaturregulert miljø for å opprettholde optimale forhold. Dette kontrollerte miljøet sikrer jevn herding av epoksyen og bevarer fargenes livfullhet

Til slutt må du sørge for å rengjøre overflaten før du påfører epoksy. Flekker eller bobler kan oppstå på grunn av støv, fett. GOERNER sørger for at alle deler er rene og forberedt før epoksyprosessen startes. Ved å følge disse instruksjonene, unngår GOERNER mange vanlige problemer og sikrer at hver enkelt oseanbølge-epoksydel blir glatt, klar og vakker

Se på disse grunnene til at grossister velger 3D oseanbølge-epoksy i stedet for de tradisjonelle flate bølgene

Hvorfor velge 3D havbølge epoxyprodukter fra GOERNER9? 3D-stilen er mer attraktiv og verdifull sammenlignet med flate. Hvis et produkt er i 3D, betyr det at bølgene virker som om de hopper ut og har dybde. Det gjør produktet mer konkret og tiltrekkende for kunder. Naturligvis blir folk tiltrukket av ting som ikke er kjedelige og som ser levende ut. Flate design med jevn, glatt epoxy vil alltid virke mindre interessant og enkelt. 3D havbølge epoxy fanger folks oppmerksomhet raskere og dypere i butikker eller på nett, fordi det er som et ekte stykke hav fanget rett foran dem

For kundene som handler i varepartier, er det avgjørende at de lagrer produkter som skiller seg ut. Når folk ser GOERNERs 3D havbølge epoxi stykker, fordi de vil kjøpe dem ettersom designene ser unike og av toppkvalitet ut. Dette hjelper butikker med å selge mer produkt og oppnå høyere fortjeneste. I tillegg kan 3D-epoxy-prosjekter se mer eksklusive og luksuriøse ut, slik at selgere kan belaste en premie på dem. Dette gjør produktene til bedre investeringer for butikker og bedrifter

En annen ting som grossistkjøpere liker med 3D epoxy i havbølge-stil, er mangfoldet. GOERNER kunne forme mange ulike bølgeformer og strukturer som forandrer seg med lys og vinkel. Dette mangfoldet appellerer til ulike typer kunder – fra de som ønsker klare og livlige bølger, til andre som foretrekker myke og rolige havscener. Flate design har rett og slett ikke samme variabilitet, siden de ser like ut uansett hvilken vinkel de betraktes fra

Til slutt er 3D epoxy-objekter med havbølgeeffekt mer robuste og nyttige. Den tykke epoxylaget beskytter også designet under mot krasj og annen skade, noe som er viktig når du transporterer produkter i store mengder. Grossister du handler med elsker GOERNER fordi våre 3D-epoxyprodukter leveres klare til visning, kvaliteten og etterspørselen er synlig, og de holder lenge på butikkenes hyller

Kort sagt har 3D epoxy-designer med havbølgeeffekt fra GOERNER bedre utseende, holdbarhet og variasjon. Det betyr også at de er det perfekte produktet for enhver grossist som ønsker noe vakkert og varig å tilby sine kunder

Innholdsfortegnelse

- Hvorfor teknikker for epoxy med bølgeeffekt er ideelle for grossistkunder

- Hvordan lage en fantastisk 3D-effekt med Ocean Wave-epoxy

- Hvordan Ocean Wave-epoxy fungerer gjør produkter bedre og mer vakre

- Typiske problemer ved påføring av oceanbølge-epoxy og hvordan man retter dem opp

- Se på disse grunnene til at grossister velger 3D oseanbølge-epoksy i stedet for de tradisjonelle flate bølgene